TracknTraceGT Implementation at Servo Lubricants, Indian Oil Corporation Ltd.

GTI has Design, engineered, developed, installed and commissioned QR code based Track and Trace system along with allied miscellaneous civil, electrical & instrumentation and mechanical works for the Lubricant Division SERVO of Indian Oil Corporation Ltd. (IOCL).

Under the contract, GTI implemented its TracknTraceGT solution across 10 plants of Indian Oil catering to over 40,000 SKUs and 10,000,000 small cap & large cap Lubricant packaging. GTI’s Solution uses QR code based methodology to provide accurate and timely decision support for multiple functional within organization, data collection and dissemination of information for each of its facilities, and any future facilities.

Features

- Process Streamlining :

- Complete Traceability :

- Warehouse Management System :

- Anti-Counterfeit :

- Loyalty Program Management :

This implementation should streamlined work processes, include thorough training for all users of the new technology, and improved the accessibility, timeliness, and accuracy of data. The system support complete material tracking and also provide IOCL with the ability to take strategic marketing decisions. The solution has all the primary packs (cans, buckets) uniquely identified, such that the same can be traced till the end of its sales life span. This is in view to prevent manufacturing errors, combat counterfeit products and improve supply chain efficiencies throughout the organization.

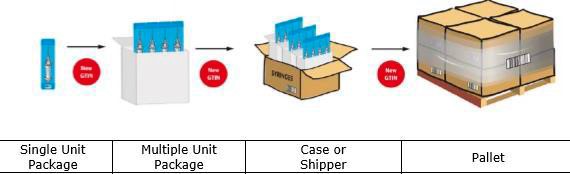

The traceability includes tracking of primary, secondary and tertiary (Can, Carton, Buckets, pallet) packing level as they are printed with QR codes data matrix code, the solution makes use of the Hardware that scans/reads/prints/maps and aggregates the QR codes applied at various levels in the packaging.

All the scenarios are covered in the plant for packing of products with the appropriate automation for boosting productivity and quality process wherever possible and required. Post plant activities, all the warehouses are covered with Warehouse Management system which enables scanning carton at the warehouse level and thus providing a point to point scanning of all cartons thus enabling end to end traceability wherever the cartons are getting scanned down the Supply Chain. Warehouse Management System ensures that the material when dispatched from the plant warehouse/contract manufacturer is tracked and the process at the CIPs (4 nos.) and CFAs (33 nos.) gets simplified. The system also allows the CIPs to be aware of what material is planned for receipt on any given day.

At the retailer and the consumer end an app is hosted by GTI, which has the facility to scan the QR codes on the each’s (SKU) as well as the cartons. IOCL officers have the feature to scan the carton as well as the SKU. The retailers will also be enabled to scan via the app. On scanning, the user will get the entire history of that particular carton/SKU so as to determine the origin, the warehouse history and also the way it reached the particular place. Also, counterfeit data is displayed at the scan. This scan can also be used for validating the stock consumption at the distributor end.

Loyalty program data is enabled in backend wherever scanned and the catalogue for the same will be available on the data base for gifts disbursement and order fulfilment.

Objectives

The objectives are many, which are tangible as well as intangible, however at present IOCL is receiving the followings benefits from this system :

- Minimizes counterfeit products in the market.

- Complete end to end track and trace.

- Inventory clarity at all nodes.

- Minimizes product/batch mismatch.

- Data for analytics for effective decision making.

- Loyalty programs enables on the barcode platform.

- Cross State Infiltration minimizes.

- Customer peace of mind.

- Tracking re-use of any SKU / bottle in supply chain.

- Avg. time spent in transit between each node along with ownership for delay.

Price Flow

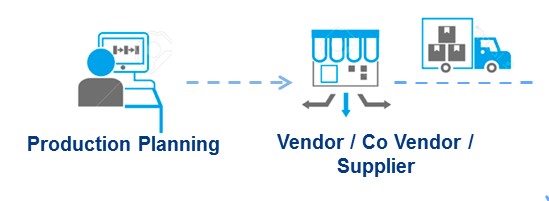

Printing of QR codes on labels at Label manufacturer end

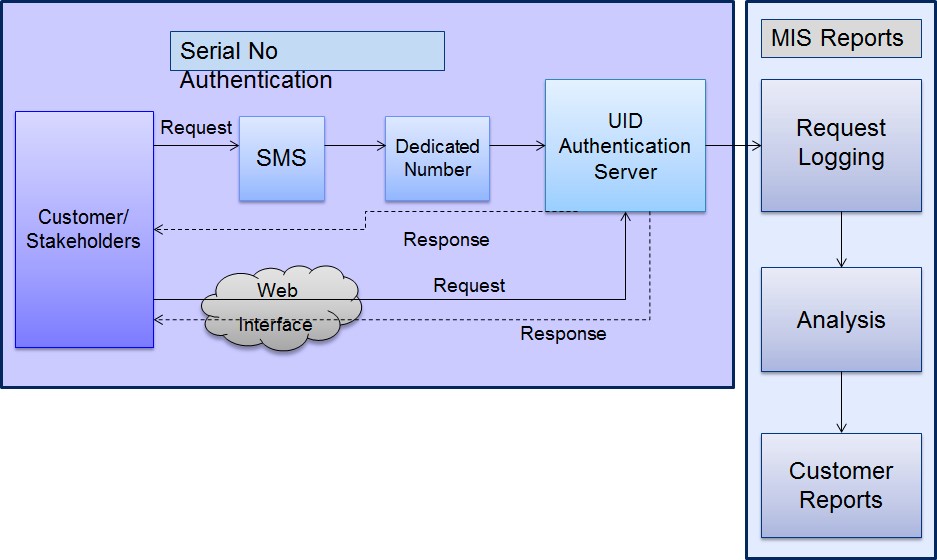

The crux of the solution is to have control over the UID’s printed and validated. We have developed an online login based on authorization of IOCL, into the software wherein they can login and generate codes online from the software. The codes will be generated on the IOCL server and label vendors can print online. The numbers generated should never be stored/ downloadable in a transferable file thus making the system fool proof in terms of randomized number protection. The numbers are to be created real time (just before printing). This generation and printing module should be working in 21CFR chapter 11 environment for Data security. Here the effort of generating codes and converting into PDF and sending will get minimized and better control can be executed.

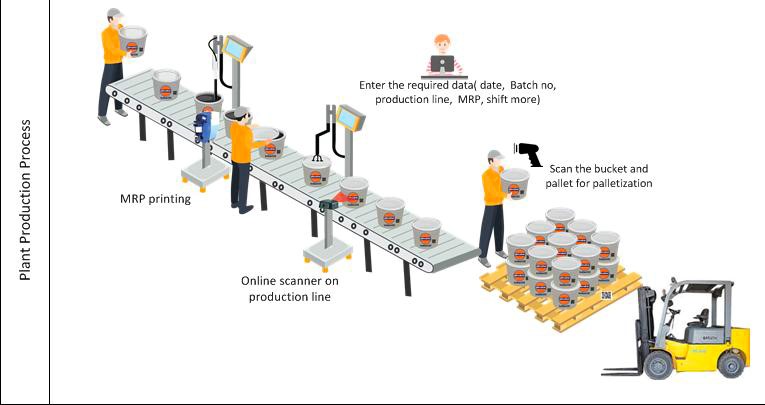

Scanning

Then after filling, capping, induction sealing, weigh checker, online inkjet / laser printer operation on the filling line, 1 QR scanner is installed online which verifies the QR code of containers, (if readable otherwise reject) with the data bank of QR codes generated by IOCL server, if match, it is forwarded for aggregation into cartons otherwise it will be rejected. Here simultaneous operation for data mapping into plant will be done, which is shared with the cloud in real time with internet connection.

Carton packing and palletizing

After all the SKUs / products are marked with uniquely identified QR codes, there is a need to aggregate the pack size into different forms and sizes. All the SKU’s are thus scanned in automatic/manual (automatic wherever possible) methods to generate a secondary QR code/barcode to be stuck on the box/carton. Multiple such packing levels can be formed within the system. QR codes with 1D linear barcodes will be used for the same. These codes will have the data of all the primaries.

Process & Transportation

On scanning the QR code or 1D barcode on the box, all the data of the primary SKUs packed gets reflected on to the system. This makes the operations easy and at the same time effective for data gathering. The pallets (different from plant to plant) have fixed barcode PVC/ metal tags, which will uniquely identify the pallet. Also the goods kept on each pallet will be aggregated such that on scanning the pallet barcode, the entire SKU level count/UID’s get reflected in the system.

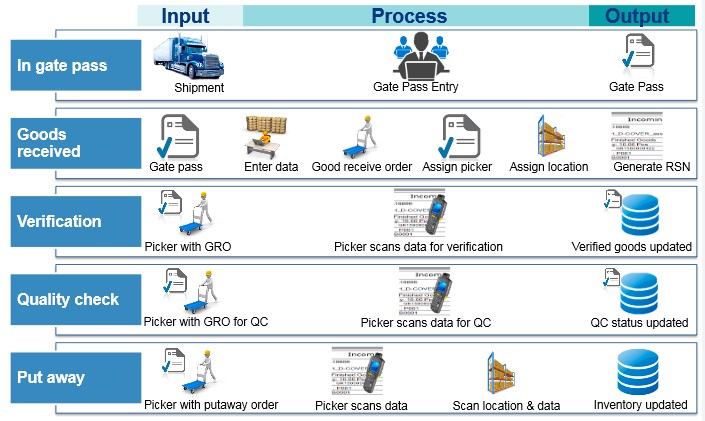

CIPs / CFAs/ Stockiest warehouse (Warehouse Management System)

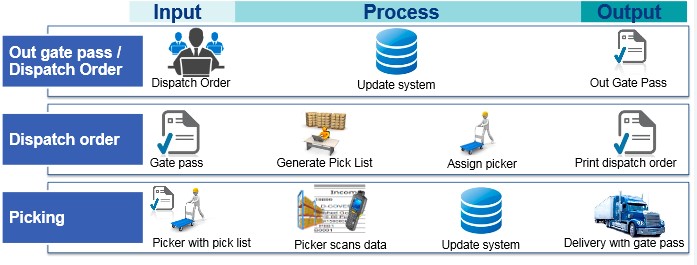

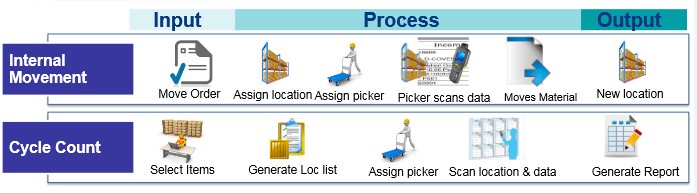

IOCL is having its own SAP based Warehouse Management System in various CIPs ( 4 nos.) and CFAs (33 nos.). GTI has integrated its system with SAP and ensured that the material when dispatched from the plant warehouse/contract manufacturer is tracked and the process at the warehouses gets simplified. The system allows the warehouse to be aware of what material is planned for receipt on any given day. It has various processes.

(a) Good Receipt Process -

(b) Dispatch Process Flow -

(c) Internal Upkeep Flow -

Mobile App

GTI has designed the Mobile app for Android / IOS (with scanning capability) for distributors, Retailers/ Consumers/ dealers/Bazaar outlets/Distributors/Retailers/Consumers use our mobile app with which they can scan and validate the stock, they will have the provision for scanning carton as well as the SKU barcode.

Anti-counterfeit

GTI’s mobile app gives feedback on the unauthenticated codes. The UID that is not available in the database will create a RED flag when scanned, immediately IOCL will be informed by Email. For codes available in the database, the app will give a GREEN go ahead for the first time scan within the area where the codes were supposed to be available.

Loyalty Program

Loyalty program enables the features of self sustaining loyalty program, analytics on the data gathered, user group wise access, Geomapping, authorization of Distributor, retailer, mechanic and consumer based on the UID such as Aadhar no, PAN or any other KYC as per IOCL instruction.

Data Analytics

GTI has provided an extensive BI tool that works with excel and visual dashboards for sales by channel, territory, end-to-end journey of any SKU with timestamp & location stamp, complete batch tracking, stock freshness, In-transit analysis, Supply Chain visibility, Goods movement, Stock level at each Supply Chain node etc.

Image Gallery

AWARD WINNING SOLUTION